NEWS ITEM January 2010

LETS CLEAR AWAY

THE SMOKE ON FIRE SYSTEM COMPLIANCE FOR MOBILE EQUIPMENT!

LOOK FOR THIS IN THE AUSTRALIAN JOURNAL OF MINING!

In December 2006, the long awaited Standard for fire suppression systems that protect mobile equipment was released. This was Australian Standard AS 5062-2006 Fire Protection of Mobile and Transportable Equipment. This standard is important as prior to this, the mining industry grappled with what were acceptable design standards for fire suppression systems protecting valuable working assetts and the production they bring. Like most Standards, there will never be concensus on what the Standard should or should not have said, however; there are some very interesting points worth noting.

LISTING . The original draft of AS5062 would require the National Association of Testing Authorities (NATA) as the body that would recognise the validity of listing bodies. Inexplicably, the standard was changed to any body concerned with testing?

TESTING COMPLIANCE. Many users of many products seek to confirm compliance to a Standard, but rarely do they bother to acquaint themselves with the actual Standard. A compliance to AS5062 does not automatically approve it for mining equipment. The Authority Having Jurisdiction must make that determination. We recommend that applications of designs be restricted to no more than five times the scale they have been tested too. This keeps predicted performance within sensible bounds. Currently we see for example fire systems with only a Pre-Engineered Listing that are tested on a one nozzle basis. These then claim standards compliance and apply their designs up to one hundred nozzles or more without any documented fire testing for large systems!

PERFORMANCE. The performance testing of fire systems other than Pre Engineered foam water spray types is not defined in AS5062. Again, this is left to the credibility of the listing body. For example, the ETI system is listed as an Engineered Foam Fire Suppression system to NFPA11. As the designer of the system, we felt Pre-Engineered testing was totally inadequate for large mining machines which represented our major market. We therefore opted for a full scale live fire test complete with direct and indirect fire demands on the suppression design. This formed the basis of our data for designing Engineered fire systems. This performance data was submitted through our listing body and was ultimately accepted after expert evaluation involving the NFPA under a process mutually recognised by NATA Australia.

INSTALLATION COMPLIANCE. AS5062 makes the risk management process mandatory in designing the fire system. AS5062 goes on to say that the handover of a compliant fire system must include a copy of The Risk Assessment, The Design Documents, The Certificate of Completion, The Service Program and drawings and/or photographic record of the installation. If you bought a fire system under AS5062 and did not get these documents, your installation does not comply! Today, suppliers of fire systems have a duty of care to provide top shelf training, detailed technical manuals and a design procedures and tools that allow accredited designers to perform these tasks competently, and actually deliver on the promise of compliance to AS5062.

CONFUSION ABOUT COMPLIANCE. Its sad to say that there are

those in the market place who mislead customers. Fortunately there are strong

laws in Australia under the Trade Practices Act meant to dissuade these

practices. There

are those who are saying that you have not got

compliance to AS 5062 unless its listed by CSIRO ACTIVFIRE! This is

simply false. While the CSIRO may generally be accepted as a credible

laboratory, it has no claim in controlling compliance to AS5062.

IN SUMMARY we recommend a few points in considering selection of a fire

suppression system claiming compliance to AS5062.

1) Spend a little time with AS5062 and understand the different classification types. The Authority Having Jurisdiction should define a limit on listings based on actual fire testing. We recommend no more than five times scale.

2) Scrutinise the listing. Is it recognised by NATA? If it claims a listing from a US or other foreign suppier, ask for details of the actual fire testing used to gain the listing. Do not automatically accept US based listings. These fire systems are designed for different climatic conditions and they are also made to meet commercial, legal and political influences that prevail in the USA.

3) Ask if the fire system is Engineered or Pre-Engineered? You may find Pre-Engineered systems are tested to very small scale and therefore limits should be imposed on their application.

4) Plan the risk assessment process. The supplier has an obligation to carry this out. It needs participation of the owner, operator, machine equipment supplier, maintenance and management. If you decline participation, you are not complying to AS5062!

5) Check that the hand over includes all the paperwork required under AS5062. Actually read it and evaluate if it has been competently done.

NEWS ITEM - August 2005

![]() ETI SOLVES RISE OF PRESSURE DILEMMA!

ETI SOLVES RISE OF PRESSURE DILEMMA!

Over the last 20 years, Rise Of Pressure sensors proved to be excellent fire detectors for diesel engine environments. However, there were two problems:

1)

The types on the market were

classified in explosives categories of international Dangerous Goods! While they were

difficult to transport and manage previously, in this last decade they have become

virtually impossible to manage.

2)

They were made using a very small

6mm tube. They typically had a design limit of 2.5 times the detector length as

a design limit. As machines got bigger, the design limits were exceeded.

ETI solved this by developing in house, a new sensor. The propellant is less volatile yet still gives reliable auto-ignition at 195 degrees centigrade. The chemicals used in our largest (2 metres) sensor only adds up to 18 grams. This is well below the declarable limit of 5Kg for the relevant chemicals under United Nations DG protocols. This means that large quantities of ETI sensors can be shipped and stored without a requirement to declare DG! Further, ETI made its sensors in a 12mm tube that allowed more propellant to give a stronger pneumatic pulse. Controlled tests have confirmed ETIs design rule allowing 6 times the sensor length in a hose run to the actuating valve.

So while others bale out when it just gets too hard, trust ETI to find the answers!

IF YOU HAVE HAD ENOUGH OF LOSS OF PRESSURE SYSTEMS CAUSING YOU HEADACHES ? -COME BACK TO RISE OF PRESSURE WITH ETI!

OR GET THE BEST OF BOTH SYSTEMS AND ASK FOR OUR DUAL SYSTEM!

NEWS ITEM - March 2009

ETI RELEASES

THE MOST ADVANCED DESIGN SOFTWARE FOR MOBILE EQUIPMENT FIRE SYSTEM DESIGN!

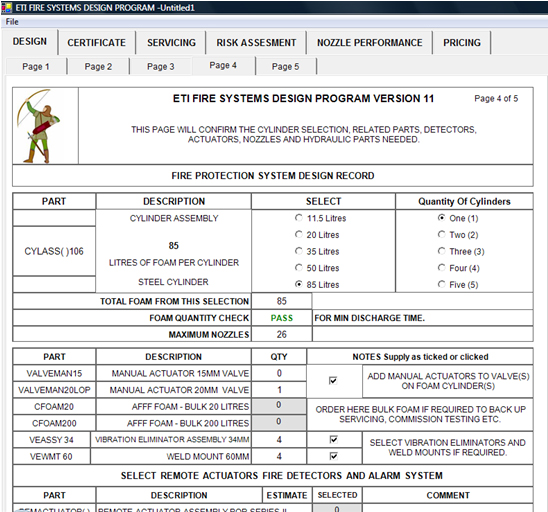

In todays world, companies providing fire protection equipment, need to make reliable, accurate and compliant designs. Business needs to estimate accurately so that neither the supplier or the customer gets disappointed with a costing error.

ETI leads the way with a higher

compliance category than other fire systems on the Australian market who only

have a Pre-Engineered listed fire system. This

meant that ETI had to have higher level design protocols that included detailed

agent and pipework calculations. Together with the release of a fully AS5062

compliant package in 2009, ETI added its comprehensive web based design

software. Only trained and approved users can use this using a PIN access.

Briefly-

1)-It is web based only to autorised users!

2)- It uses a Microsoft .net platform as an operating system making it compatible with all common Microsoft operating systems.

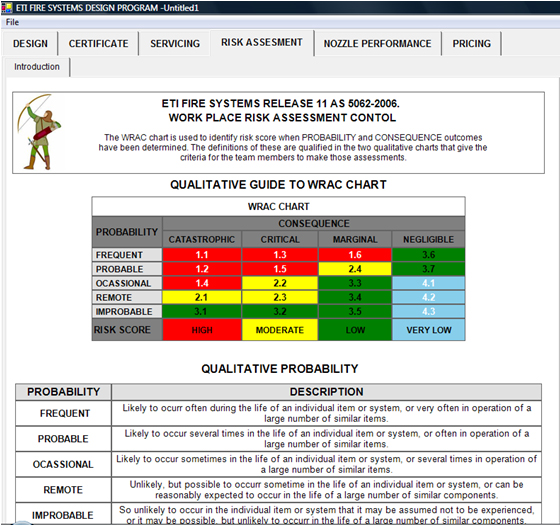

3)- It gives the user a comprehensive RISK ASSESSMENT package that allows the designer to work with the customer through the mandatory risk assessment process.

4) It then has an easy to use design module that ensures that a compliant design results with the program checking equipment selections and performing the agent and pipework calculations.

5) it provides a detailed bill of materials and cost estimating platform so the ETI distributor provides an accurate and reliable quotation.